Laser Cutting

What is laser cutting?

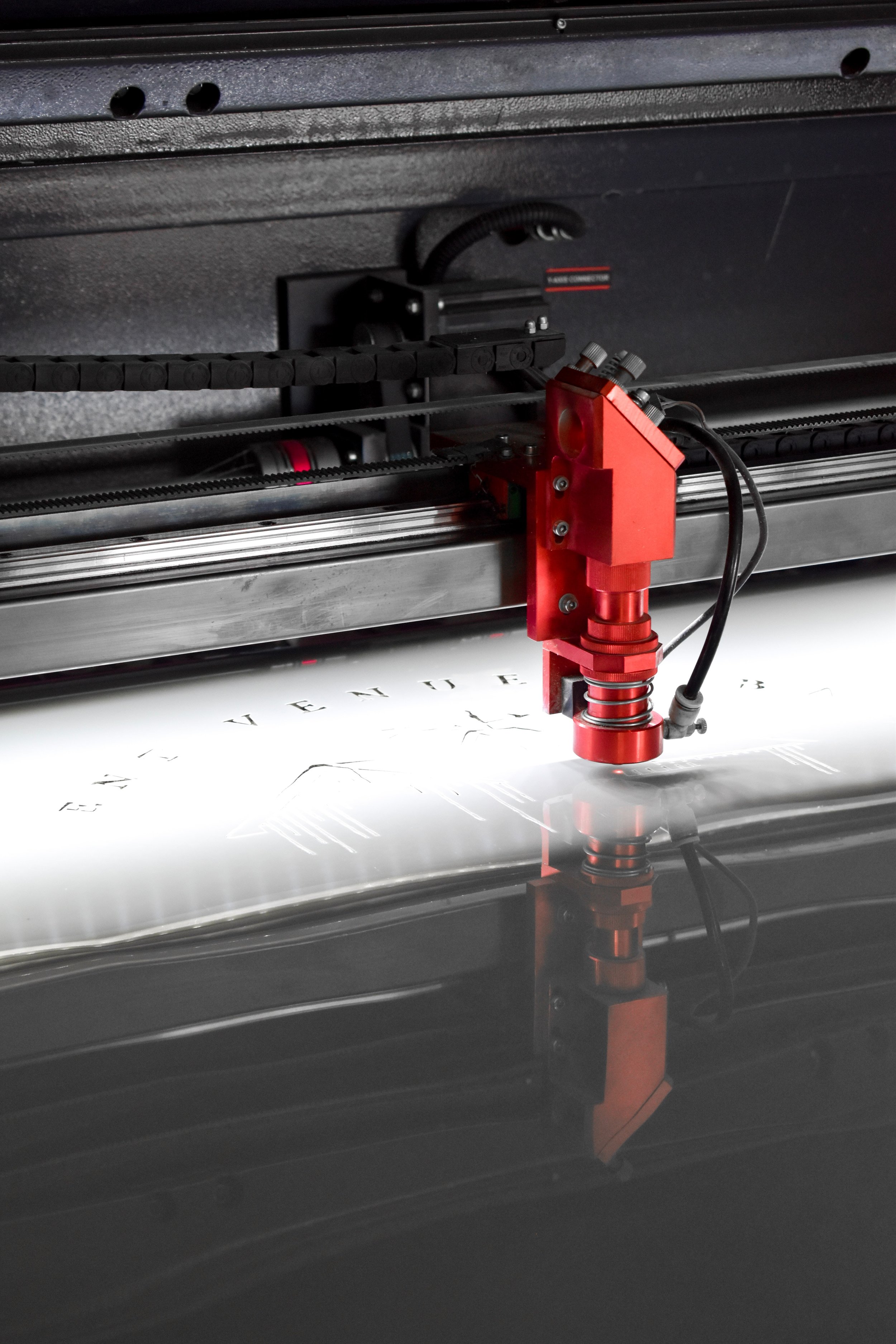

Laser cutting is a CNC fabrication process that uses a focused laser beam to score, raster, and cut both simple and complex 2D designs onto a variety of material sheets. The laser beam is directed onto the material via a series of mirrors and focused onto the material via lenses. A computer software is then used to generate the tool path of the laser for each unique design. Software is also used to control the speed and intensity of the laser beam to ensure the laser will work with the desired material and decrease the likelihood of a fire. Laser cutters are quick and efficient tools when it comes to producing parts with a flat geometry. For this reason, we strongly encourage students to use the laser cutters for flat parts instead of 3D printing.

Using the MECE Lab Laser Cutters

Training

To use the laser cutters in our lab, students must first be trained by a lab technician or super user or have successfully completed the Intro to Machining course. This training will cover a brief introduction to LightBurn for file processing, instructions on properly running all hardware associated with the laser cutter, and safety precautions that must be followed every time the laser is used.

If you would like to request a training with a lab technician, you can schedule it here. Please note that the Makerspace laser cutter training is NOT equivalent to a training in the MECE lab, as we use different software and hardware. You must be trained in each space respectively.

Reserve Time on the Lasers

To reserve time on the lasers, visit our Machine Sign Up Sheet. You must use your UNI to sign up for the laser cutter. Time slots are 30 min each and there is a limit to 1 hour total a day per student. As a reminder, students must be trained by MECE lab staff before signing up for a time slot. See above for more information.

Our lasers

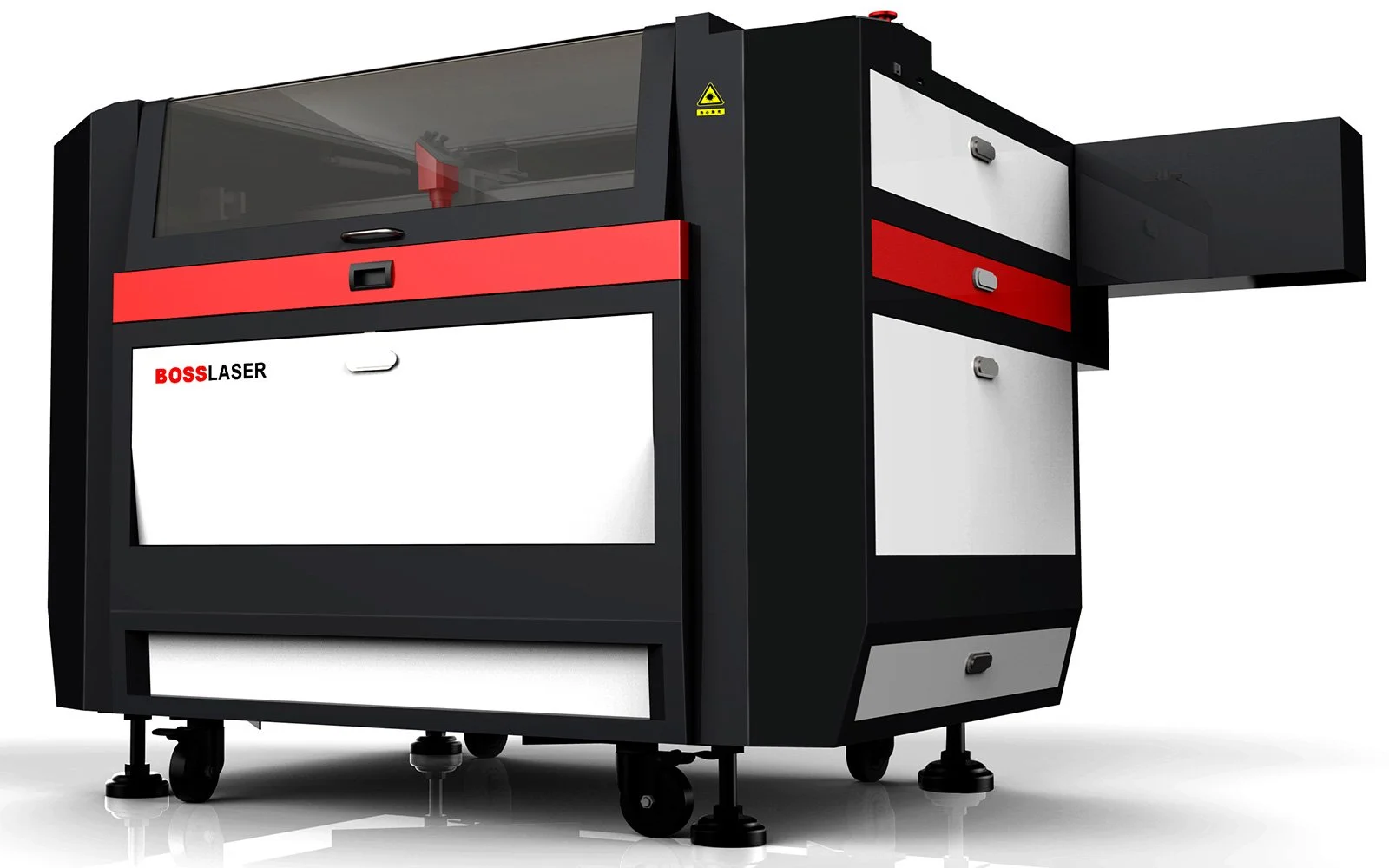

Boss Laser LS-2440

Laser Power: CO2 105 Watts

Cutting Area: 39.75” x 23.6”

Z - Table Travel: 7.5”

Laser Cutting FAQs

-

Acrylic (up to 1/4” thickness), cardboard, paper, and wood (up to 1/8” thickness) are all safe to cut on the laser cutters.

Materials that CANNOT be used on laser cutters include:

1) Polycarbonate or PVC, as they will produce toxic fumes

2) Metals or other reflective materials, as they can reflect the laser in unwanted directions and cause damage to equipment and bodily harm

If you are unsure if it is safe to use an unlisted material, ask lab staff for guidance.

-

Lightburn supports the following file types: ai .pdf .sc .dxf .gc .gcode .nc .hpgl .plt .rd .scpro2 .svg .lbrn .lbrn2 .bmp .jpg .jpeg .png .gif .tif .tiff .tga .webp

If you designed a unique part in SolidWorks, you can directly export the face of the part you need into a supported file type.

For simple geometric shapes, you don’t need to prepare a file and can instead draw directly inside LightBurn using the software’s drawing tools.

-

Our stock material is stored next to the laser cutters and is available to all students for both course and personal projects. Large usable material scraps are kept inside a wooden bin. Small usable material scraps are stored in drawers according to material type and thickness. New material sheets are to be used only when no scraps would work for your project. New sheets of acrylic are given out only with prior lab staff approval.

Please throw away scrap that is no longer useful (i.e. material pieces smaller than the palm of your hand).

If we are running low on stock material, please let the lab staff know so we can place a refill order.

The following is a list of the standard material thicknesses we keep in our lab:

1) Acrylic thicknesses: 1/16”, 1/8”, and 1/4”

2) Wood thicknesses: 1/8”

-

The laser cutters can only be used by those who have received a proper MECE Lab training (not a Makerspace training) when a lab staff member or super user is present in the lab. In the event of a laser cutter fire, it is important to have lab personnel present to safely and effectively respond to the fire.